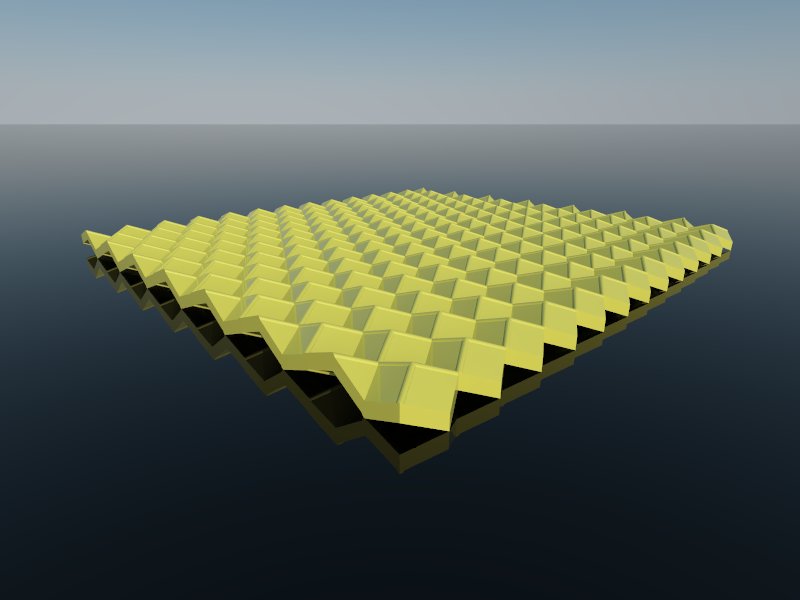

with a new cell geometry that is better accepted by the bees

Silicone matrices with the new cell geometry to build foundation molds -> read more

.

Available at the shop.

.

.

.

- .

. - Wisa Wire plywood is practically indestructible and is designed for use as flooring in the transport industry i.e. in trailers, horse boxes and railway wagons and building applications such as warehouses, loading platforms and scaffolding:

.

.

. - Water cooling both at the top as well as at the bottom of the mold is guaranteed by a copper plate with a welded copper tubing coil. Since copper is a very good conductor of heat, cooling is optimal. The copper plate is screwed onto the Wisa Wire plate:

.

Cooling is also possible with a closed system consisting of a 200 liter water drum and a small electric pump. This saves a lot of water!

Cooling is also possible with a closed system consisting of a 200 liter water drum and a small electric pump. This saves a lot of water!

. - Thickness adjustment is possible thanks to 4 adjustment screws and oblong holes in the hinge.

To adjust:

Open the hinge screws slightly and loosen the adjustment screws. Set the top at the bottom without distance and then unscrew the adjusting screws until they touch the aluminum rail. The desired thickness of the wax foundation sheet can be set by loosening the 4 screws the same amount. One lap is 0.8 mm thickness. Tighten the screws of the hinge and finished:

.

.

. - The mold is opened by a lever mechanism:

.

.

. - A great advantage is that the silicone base is molded in one piece. This means that the silicone edges are not glued to the matrice, but they and the matrice are one piece. Therefore the wax does not touch metal parts and can not get into cracks, where it could adhere tightly:

.

. - optional with a silicone apron to collect the wax:

.

.

.

At the moment only available in Langstroth size (420mm x 200mm) and in cell sizes of 4.9mm and 5.1mm.

.

The new cell geometry

Dee Lusby writes in her webpage that one should use

foundation without pronounced cell walls.

Well I made tests and to my surprise came out the following:

I added to several hives complete supers with 11 frames. Alternating foundations with the new cell geometry and foundation after the swedish model, which has cell imprints similar to what is used anywhere. A swedish, a new one, a swedish, a new one ……. all the box like this. It was used the same wax and the same cell dimensiones between 4,8 and 4,85mm.

All this with a good nectar flow.

Next day all the hives had built combs in the frames with foundation of the new geometry and the swedish ones were not built.

So the decision matured to build foundation molds with this new cell geometry since the foundation on the market almost ] all have large errors en cell measurement.